I’m not sure who the ordnance bureaucrat was that determined that crimping primers in place was necessary—perhaps a reader with a better grasp of military ordnance history can enlighten me. I’ve heard it offered that crimping primers in place makes military ammo in military arms and fired under military conditions more reliable. Maybe so, but for those of us using old military brass it’s another step in brass prep that we’d just as soon pass upon. Crimped primers have found their way into modern commercial ammunition as well. Any manufacturer who loads for the military leaves the crimp feature in their loading operation probably because it would cost too much to remove and replace it when they change from military to commercial ammo.

I’m not sure who the ordnance bureaucrat was that determined that crimping primers in place was necessary—perhaps a reader with a better grasp of military ordnance history can enlighten me. I’ve heard it offered that crimping primers in place makes military ammo in military arms and fired under military conditions more reliable. Maybe so, but for those of us using old military brass it’s another step in brass prep that we’d just as soon pass upon. Crimped primers have found their way into modern commercial ammunition as well. Any manufacturer who loads for the military leaves the crimp feature in their loading operation probably because it would cost too much to remove and replace it when they change from military to commercial ammo.

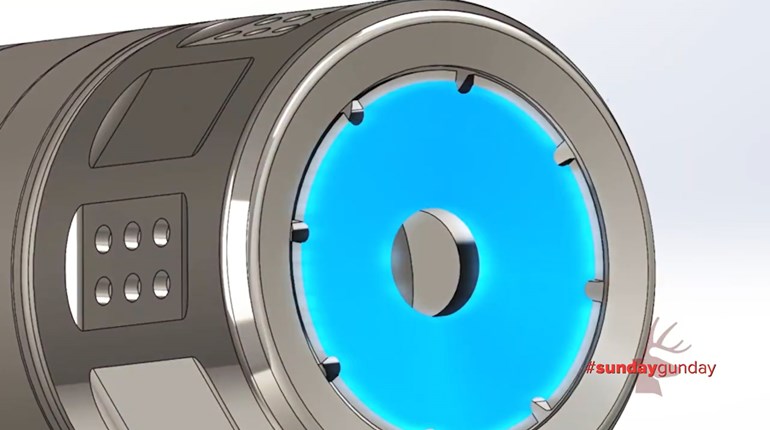

In the old days primers were stake-crimped into the primer pocket. A staking tool—a sort of square-pointed punch—would put three crimps around the rim of the primer pocket after the primer was seated. Now the crimps are annular—meaning there is a circle of metal around the rim of the pocket to ensure it doesn’t blow out during a fire fight.

The crimp does not make it any more difficult to remove a spent primer, but you cannot seat a fresh primer with a crimped pocket. There are two ways to deal with crimped primer pockets. Many handloaders simply ream it out with a primer pocket reamer—really old school guys used a pocket knife. It’s effective, but I hate to remove metal from a cartridge case, so I use the much-more-labor-intensive primer pocket swager. This is a tool that utilizes a rounded nub on the ram of your press to swage or push metal out of the way and ensure the pocket is the proper dimension to hold the new primer.

Trouble is, in order to make it work you have to slide the case onto a mandrel located at the top of the press and then bring the ram up to contact the case, and finally ram it all home to remove the crimp. It’s a tedious task and one fraught with injury potential. If your timing gets out of whack, it’s real easy to get that ram up and catch your thumb and/or index finger between the ram and the bottom of the die. I’ve done that more than a few times, and it really upsets my day.

In reality, since I am currently loading prairie dog ammo, I should go ahead and ream and uniform the primer pocket. Doing so takes another variable from the accuracy devil, but doing so is equally tedious and time consuming—which is my biggest beef when I am prepping some 2,000 rounds of .223 Remington brass. It reduces the finger pinching bug-a-boo, but slipping up can run a sharp reamer edge into the hand as well, so we’re back at the original conundrum.

An aside: Don’t expect to find primers crimped solely in military calibers. A friend found his .204 Ruger cases from Federal had crimped primers, and it took a while to find a solution since there aren’t any .20-caliber mandrels made for swaging dies.

I’ll probably just continue to swage the pockets of this horde of brass—partly due to inertia and partly due to the fact that they are not all made by the same manufacturer. I’m not a good enough shot in the field to make use of the .1- to .125-moa difference that might occur when reaming the pocket. So if anyone should show up over the next couple of days and hear some profanity being launched from within my shop, they’ll know I pinched my fingers again.