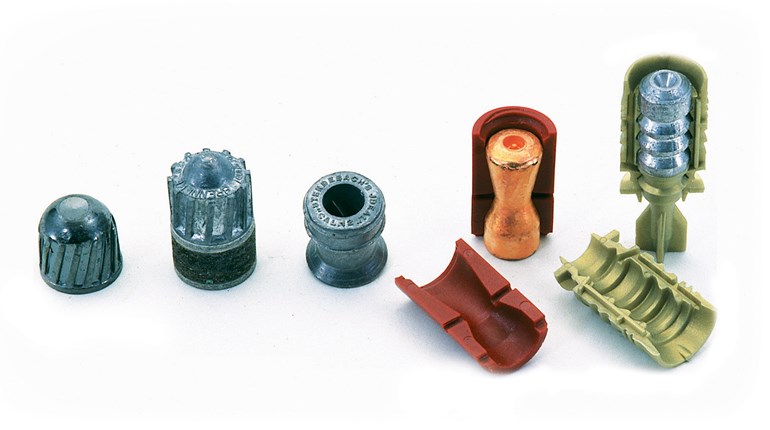

With the introduction of the sabot in the late ’80s, shotgun slugs were revolutionized. The projectile no longer was limited to soft lead and could utilize technology available to modern rifle bullets. Here’s how a sabot (pronounced "say-bo") slug works: The bullet is fitted inside a plastic sleeve, or "sabot," that engages the rifling in the shotgun’s bore and imparts spin on the slug. Once it’s free from the shotgun and in the air, the sabot opens and releases the slug. The slug continues to the target while the sabot quickly loses velocity and falls to the ground a few yards downrange.

One of the early innovations in sabot slugs came from the Hastings company. It used a slightly different approach. Rather than encasing a bullet within the sabot that released it once the two were free of the barrel, Hastings’ design (called a “Pressure Sabot" by the company) used a sabot that stayed with the slug all the way to the target. The design is full-diameter and about as long as a conventional shotgun wad. It is one piece, and it does not release the slug while in flight. Its job is to hold the slug, engage the rifling to spin the slug and then fly with the slug to help stabilize it.

The slug itself is much different than any other shotgun slug, as it is mushroom-shaped with a large, long stem inserted into the wad with a full-caliber “cap” on top. Hastings called it the “Hammerhead.” This weight-forward design flies with the slug firmly embedded in the sabot all the way to the target. The huge, full-caliber slug cuts a big, clean hole as it enters; as the slug expands that hole grows even bigger. As one guy said, “When it hits a target it looks like a sparrow flew through, and that’s before it expands!”

I remember the first deer I shot with this type of slug. There were two big bucks chasing a doe just inside a tree line. When they passed through an opening I shot. Nothing happened for about a minute, and then a buck stepped out into the clearing. There was no doubt it was my buck, because Stevie Wonder could have seen the huge hole leaking blood. I quickly followed with another shot, but I doubt it was necessary.

These slugs have a reputation for excellent accuracy in a variety of rifled barrels, and they have maintained a loyal following with hunters who trust the design.

In addition to the Hastings, the Remington Buckhammer line of shotgun slugs used the same design concept. But as new “gee-whiz,” highly engineered slugs continued to emerge, particularly the high-velocity designs, the fickle American public moved on and sales slumped. Hastings went out of business in December 2009 and Remington dropped the Buckhammer in 2010. That effectively ended availability of this style of shotgun slugs.

Still, there is a rather large and quite knowledgeable segment of serious slug gun hunters who understand the concept and performance of the full-caliber, attached-sabot slugs and who still want this design for hunting. Now they can find it in Rottweil Laser Plus sabot slugs offered in the United States by RUAG Ammotec USA. In fact, RUAG loads the ammo with the same load data, slugs and sabots as the Hastings ammo.

Laser Plus slug ammo is offered in 12- and 20-gauge, both in 23/4-inch and 3-inch. The 12-gauge slugs weigh 11/4 ounces, (547 grains) and have a published muzzle velocity of 1500 fps for the 23/4-inch load and 1625 fps for the 3-inch.

The 20-gauge slugs weigh 15/16 of an ounce (410 grains), and have a published muzzle velocity of 1475 fps for the 23/4-inch load and 1600 fps for the 3-inch.

Both performed well in my shotguns, and it was amazing to see the huge holes they punched in the target and backstop. I think disciples of Hastings and Buckhammer slugs will be pleased with this new line of deer-hunting shotgun slug ammo.