Bowhunters should optimize their arrows to gain maximum penetration (no matter what anyone says, there is no such thing as too much penetration), maximum accuracy and a flat trajectory. Achieving each requires compromises. Here’s how I select and design my hunting arrows.

What’s the Optimal Weight?

Lightweight arrows produce a flatter trajectory, making distance estimation not quite as critical. On the downside, they absorb less of the bow’s energy (so they don’t penetrate as well) and they make the bow noisier. The best compromise between speed, penetration and noise is an arrow that weighs between 6.5 and 7 grains per pound of maximum draw weight. In other words, if you shoot a 60-pound bow, your finished arrow, complete with broadhead, should weigh between 390 and 420 grains.

Where’s the Best Balance Point?

Easton’s technical people recommend a balance point that is 9 to 11 percent forward of the center of the shaft. Don’t bog down in the math, just select a broadhead that weighs one-third as much as the shaft. If the shaft weighs roughly 300 grains, you should shoot a 100-grain broadhead.

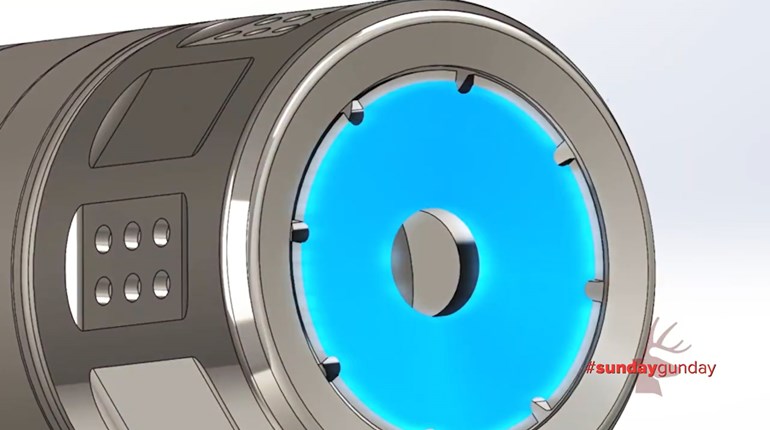

What Diameter?

Small-diameter arrows penetrated better than larger-diameter arrows of the same weight in all the testing I have done. In some cases, the difference was greater than 30 percent. I like Easton’s HIT series shafts (Axis, Epic, Full Metal Jacket, Super Slim).

Long or Short Fletchings?

Use the greatest degree of helical offset your fletching jig (or the local archery shop’s jig) can apply when fletching arrows. Couple this with today’s drop-away rests and you will not have any problems. I never use anything longer than 4 inches and I don’t know many bowhunters who do. In fact, many serious bowhunters are using 2-inch, high-profile vanes. They are made of a stiff plastic compound that resists flapping so they stabilize flight quickly and weigh less. I’ve tried them, but being naturally conservative, I still use 4-inch vanes. I tested Quik Spin vanes from New Archery Products this past season as well, and was impressed.

Carbon or Aluminum?

With the popular use of drop-away and full-capture arrow rests, fletching contact is a thing of the past. Now there is no reason not to shoot the smaller-diameter carbon arrows. Carbon is more durable than aluminum and offers many weight options.

What Broadhead?

Accuracy is a bowhunter’s No. 1 responsibility. For that reason, I like broadheads that have limited blade surface area so they don’t steer the arrow dramatically if the bow is not perfectly tuned. I shoot medium-cutting diameter (11/4- to 11/2-inch) mechanical heads. Because of their conservative size, these don’t inhibit penetration. Fixed-blade heads with cutting diameters in the range of 11⁄8 to 13⁄16 inches with short, compact blades also produce good accuracy at today’s arrow speeds.

Build Your Skills

You can test shaft, insert and broadhead straightness by spinning the arrow on the palm of your hand or by laying it in a cradle and turning it slowly while comparing the tip of the broadhead to a fixed point. It shouldn’t vibrate at all when spinning and shouldn’t waver when turning. I use the Arrow Squaring Device from G5 Outdoors on every arrow I build to assure that the end of the arrow is perfectly square with its centerline.