Rifle and pistol bullets have changed dramatically over the last few decades, but shotgun shell technology hasn’t kept that pace. Sure, there have been improvements over time, but today’s lead shotshell is very much the same as it was 50 years ago. And the shotshell might not have changed at all were it not for legislation that reduced and then banned lead shot for waterfowl hunting. In the late 1980s, the first of those bans were enacted, and by 1991 lead shot was outlawed for waterfowl hunting across the country.

There’s a very sound reason why shotshell technology hasn’t changed much since the early 20th century—it hasn’t needed to. Lead pellets driven at a reasonable velocity are lethal on game, and the price of lead ore allows for shot to be made relatively inexpensively, so the average shooter can burn up 100 rounds at the clays course on a Sunday afternoon and still afford groceries.

But legislation requiring the use of non-toxic shot for waterfowl left duck hunters in a lurch. Lead was out, and the most affordable alternative was steel. But while steel was harder than lead and non-toxic, it was also less dense than lead shot. Lead shot has a density of around 11 grams per cubic centimeter (g/cc), while steel’s density is 8 g/cc, and since kinetic energy is a measures of mass multiplied by square velocity, hunters who switched to steel realized immediately that, with pellets of equal size, steel didn’t kill as effectively as lead.

Realizing that steel pellets would never kill as effectively as lead, hunters sought out a denser non-toxic alternative. Bismuth was one option, but pure bismuth has a density of roughly 9.7 g/cc and the cost was prohibitive compared to steel. HEVI-Shot came out with their own non-toxic alternative that boasted a density better than lead at 12 g/cc, but it too was expensive.

The Tungsten Turnaround

The element tungsten was first identified in the late 1700s, and during World War II, tungsten was utilized to a limited degree by the German military for anti-tank projectiles. In its pure form tungsten has the highest melting point of any metal—over 6,000 degrees Fahrenheit—and a density of 19.3 g/cc. That makes tungsten very dense—on par with uranium—that extremely high density is what makes tungsten a great option for hunting ammunition.

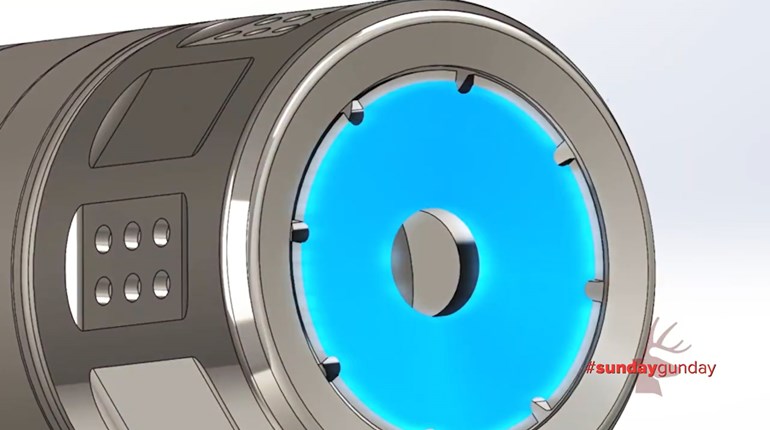

There are tungsten reserves all over the world with the largest suppliers of raw materials being China, Russia and Vietnam. Because tungsten in its pure form is brittle and difficult to work, an alloy of the metal would be necessary if tungsten could ever be considered as a viable alternative to existing non-toxic shot materials. Enter Tungsten Super Shot (TSS), an alloy comprised of 95 percent tungsten and 5 percent nickel and iron powder. TSS is easier to work than pure tungsten and more affordable, yet at 18 c/cc it is only slightly less dense than pure tungsten. TSS is 60 percent denser than lead and over twice as dense as steel, and that makes it an extremely efficient non-toxic alternative.

Consider this: one No. 9 pellet of TSS has a mass similar to a No. 5 lead pellet, so at equal velocities (the formula for kinetic energy, remember, is mass times velocity) that No. 9 pellet hits with just as much energy as a No. 5 lead pellet and it hits harder than a No. 4 steel pellet. And since No. 9 pellets are considerably smaller than No. 5s (there are about 360 No. 9 pellets per ounce and roughly 175 lead pellets per ounce) you can stuff a lot more No. 9 pellets into a single shotgun shell than you can No. 4s. A 12-gauge load of No. 5 lead contains roughly 230 pellets whereas a 1⅜-ounce load of No. 9 holds almost 500 pellets. And since each of those pellets hits with almost identical energy, it’s clear to see why TSS is so effective.

Smaller pellet size offers yet another advantage: better penetration. Because penetration is inversely proportional to surface area, smaller pellets penetrate more deeply than larger pellets when mass and velocity are equal. This disparity in penetration depths shows up clearly on ballistic gels tests. Small pellets are less affected by wind drift because of their small surface area, too. In gel tests, lead No. 5 pellets fail to reach 1.25 inches of penetration in ballistic gel somewhere around 60 yards. No. 9 TSS loads at the same velocity penetrate 1.25 inches deep at more than 80 yards.

Another benefit of TSS is its hardness. Lead is quite soft for a metal, and as a result the inevitable collisions that occur among pellets in a shot column as they exit the barrel result in pellet deformation. That, in turn, results in lots of fliers and fewer pellet impacts. TSS, by contrast, is very hard and those impacts don’t alter the pellets round shape and cause it to veer off course in flight.

What Does This Mean for Hunters?

A lot, actually. Since every No. 9 TSS pellet hits with the same energy as a No. 4 load the introduction of TSS shot makes sub-gauge shotguns far more effective, efficient killing machines. Numbers don’t lie, but I’ve seen the effects of TSS shot first-hand on birds in the field. After last turkey season, I compared notes with other hunters who had killed gobblers using TSS and the results were impressive across the board. The consensus was that shots of 30 to 40 yards on mature birds were quite feasible with a .410-bore shotgun. The farthest official turkey kill with TSS was 62 yards, but I’ve heard of multiple hunters killing birds beyond 70, though I cannot personally verify those claims.

I can, however, verify that TSS shot turns the mild-mannered .410-bore shotgun into an efficient duck hunting tool at moderate ranges. While I was on a hunt with Apex Ammunition co-owner Jared Lewis at Beaverdam Lake last fall I had a chance to witness him killing mallard drakes between 30 and 40 yards every day with his .410, and there were very few cripples. In most cases, when those birds hit the water they were stone dead.

There is a downside to all this, and that is TSS is expensive. Federal Premium lists its Heavyweight TSS .410-bore ammo at $38.99 per box of 5 rounds, and a box of 12-gauge TSS carries an MSRP from around $70 to $80, though street prices are typically lower. Apex TSS Waterfowl ammunition is priced at $60 per box of 10 rounds. Both Federal and Apex offer products from their custom shop, so you can have a TSS round loaded to your exact specifications. And, of course, there are various TSS blends that use steel or other non-toxic metals and cost considerably less.

Is TSS worth paying between $5 and $10 a shell? That depends on your budget and how much you shoot. You won’t be seeing TSS trap loads coming out any time soon, but if you shoot your turkey gun once or twice a year, it’s worth a little extra money for the reach and killing power TSS offers. I can’t tell you how many gobblers I’ve had hang up just outside shotgun range, and I’ve often wished I had about 20 additional yards of effective range with my shotgun. TSS grants that. It is also extremely effective on waterfowl, but how practical TSS is depends, again, on your budget and the number of times you shoot. There are places hunt where a two-bird day is good, and for that, TSS and TSS blend ammo doesn’t seem outrageous.

TSS is spendy, but it isn’t a gimmick. There’s sound science behind it, and I assure you that there’s nothing else you can legally stuff into a shotshell that kills with more authority. Historically, shotshell technology hasn’t progressed rapidly, but TSS is a legitimate upgrade over anything that has come before it.